What Limestone Machinery Is Used In Limestone Processing?

Source:nclirik

Posted:2023-12-19

Limestone machinery typically refers to equipment used in the mining, processing, and manufacturing of limestone products.

Limestone is a sedimentary rock composed primarily of calcium carbonate, and it is a crucial raw material in various industries, including construction, agriculture, and manufacturing. Here are some types of machinery commonly used in limestone-related processes:

Here are some types of machinery commonly used in limestone-related processes:

Each piece of equipment plays a crucial role in the overall process of extracting, processing, and delivering limestone products to various industries. The efficiency and effectiveness of each stage contribute to the quality and characteristics of the final limestone product.

Shanghai Clirik Machinery Co.,Ltd. specializes in the production of various limestone crushing and grinding equipment.

Welcome to contact us for complete limestone processing solutions.

Limestone is a sedimentary rock composed primarily of calcium carbonate, and it is a crucial raw material in various industries, including construction, agriculture, and manufacturing.

1. Mining Equipment:

Drilling Equipment:

- Purpose: Creates boreholes in the rock for the placement of explosives.

- Types: Rotary drills or drill rigs equipped with drill bits designed for limestone.

Blasting Equipment:

- Purpose: Breaks down large limestone deposits into manageable sizes.

- Process: Explosives are placed in the boreholes created by drilling, and controlled blasting fractures the limestone.

Excavators and Loaders:

- Purpose: Transports blasted limestone from the quarry to the processing plant.

- Types: Front-end loaders and large-capacity dump trucks.

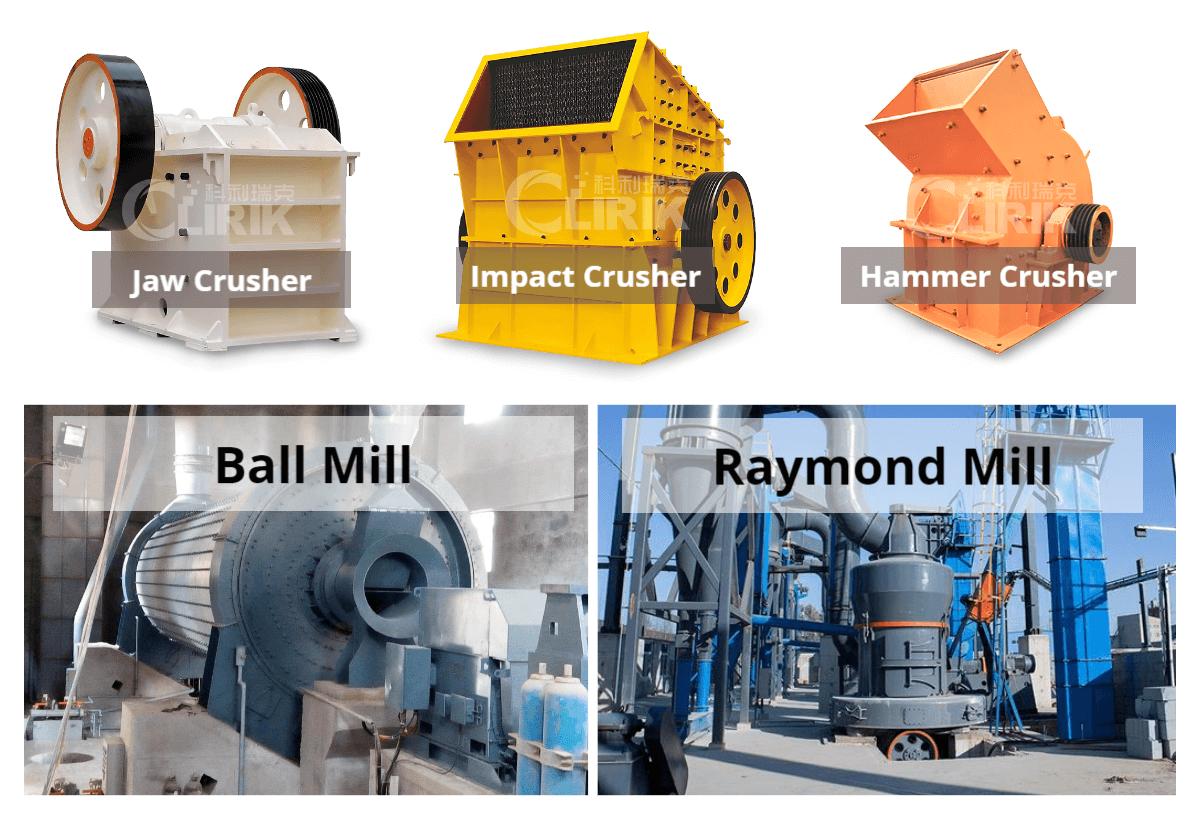

2. Crushing and Grinding Equipment:

Jaw Crushers:

- Purpose: Primary crushing to reduce large chunks of limestone to a manageable size.

- Operation: The jaws exert pressure on the limestone, breaking it down.

Impact Crushers and Hammer Mills:

- Purpose: Secondary crushing to further reduce the size of limestone particles.

- Operation: High-speed impact or hammer blows shatter the limestone into smaller fragments.

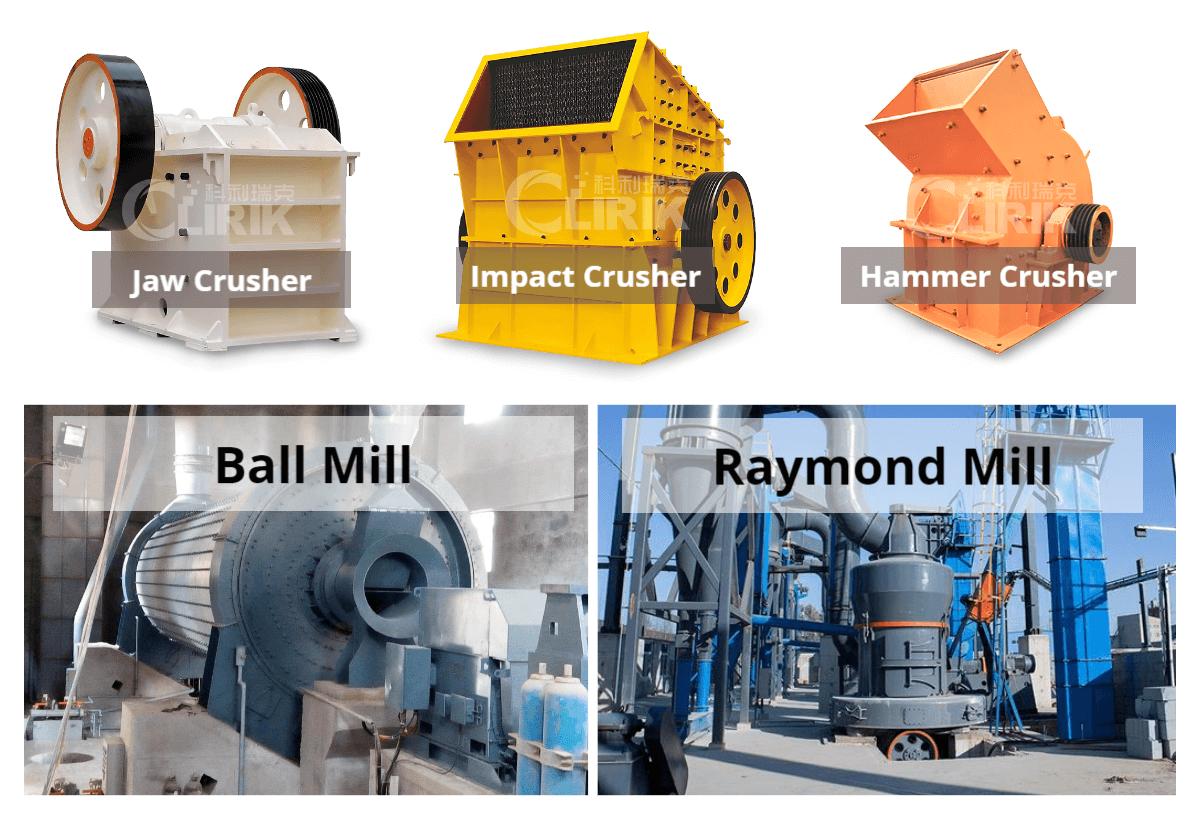

Grinding Mills:

- Purpose: Reduces limestone to a fine powder for various applications.

- Types: Ball mills or Raymond mills crush and grind limestone into a powder.

3. Screening Equipment:

Vibrating Screens:

- Purpose: Separates crushed limestone into different sizes based on particle size.

- Operation: Screens with different-sized openings allow for classification of limestone particles.

4. Material Handling Equipment:

Conveyors and Bucket Elevators:

- Purpose: Transports limestone between different stages of processing.

- Operation: Conveyors move limestone from the quarry to the crusher or from the crusher to storage silos.

5. Calcination Equipment:

Rotary Kilns:

- Purpose: Used in the calcination process to produce quicklime.

- Operation: Limestone is heated to high temperatures in a rotating kiln, resulting in the decomposition of calcium carbonate into quicklime and carbon dioxide.

6. Hydrating Equipment:

Hydrators:

- Purpose: Adds water to quicklime, producing hydrated lime.

- Operation: Quicklime is mixed with water, causing a chemical reaction that produces hydrated lime.

7. Packaging and Transport Equipment:

Bagging Machines:

- Purpose: Packages the final limestone products for distribution.

- Operation: Bags are filled with specific quantities of the processed limestone.

Trucks and Railcars:

- Purpose: Transports finished limestone products to end-users.

- Varieties: Trucks for short-distance transportation, railcars for longer distances.

8. Environmental Control Equipment:

Dust Collectors and Scrubbers:

- Purpose: Controls and minimizes dust emissions during processing.

- Operation: Collects airborne dust particles and may involve wet scrubbing to remove pollutants from exhaust gases.

Each piece of equipment plays a crucial role in the overall process of extracting, processing, and delivering limestone products to various industries. The efficiency and effectiveness of each stage contribute to the quality and characteristics of the final limestone product.

Shanghai Clirik Machinery Co.,Ltd. specializes in the production of various limestone crushing and grinding equipment.

Welcome to contact us for complete limestone processing solutions.

Related Newsmore >>

- Happy New Year 2026!2026-01-01

- CLIRIK Welcomes a Surge of Visitors During CHINACOAT 2025 Season — Free Shuttle to Pudong Showroom2025-11-25

- Ultrafine Grinding of Recovered Carbon Black (rCB) Using HGM Mill2025-10-23

- HGM Ultrafine Grinding Mill for Limestone in Cement Industry2025-10-15

- Happy China National Day 20252025-09-29

- CLIRIK Ships HGM Mill to India: Fine Limestone Powder for Rubber & Plastic Fillers2025-09-25