HGM125L Ultrafine Grinding Mill For Bauxite Processing

Source:nclirik

Posted:2022-11-16

Project Background

Our domestic customer bought HGM125L ultrafine grinding mill grinding bauxite to be D98=325mesh (40 micron) powder, the real output capacity is 5.5-6 tons per hour, the machine is 24 hours working without stop, one ton bauxite powder's pure profit is about $30 profit, customer very satisfied and ready to buy another two sets HGM125L mill.

- Machine model: HGM125L

- Material: bauxite

- Output size: 325 mesh, 98% passing

- Actual output capacity: 5.5-6 tons per hour

What is bauxite?

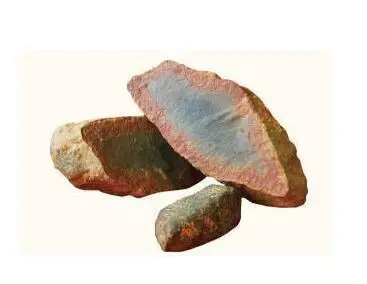

Bauxite is the most important aluminum-bearing mineral, and its main components are Al(OH)3, boehmite, diaspore, and goethite, hematite, and quartz.

The application field of bauxite has two aspects: metal and non-metal. It is the best raw material for the production of metal aluminum, and it is also the most important application field. Its consumption accounts for more than 90% of the total output of bauxite in the world. Although the proportion of bauxite in non-metallic aspects is small, it has a wide range of uses. Mohs hardness 2.5-3.5.

What are the uses of bauxite ore?

Bauxite ore has various uses:

- 1. Aluminum smelting industry. For national defense, aviation, automobiles, electrical appliances, chemicals, daily necessities, etc.

- 2. Precision casting. The bauxite clinker is processed into fine powder to make a mold and then precision cast. For military, aerospace, communications, instrumentation, machinery and medical equipment sectors.

- 3. For refractory products. High alumina bauxite clinker has a refractoriness of up to 1780℃, strong chemical stability and good physical properties.

- 4. Aluminum silicate refractory fiber. It has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, small heat capacity and mechanical vibration resistance. Used in steel, non-ferrous metallurgy, electronics, petroleum, chemical industry, aerospace, atomic energy, national defense and other industries. It is to put high-alumina clinker into a high-temperature electric arc furnace with a melting temperature of about 2000-2200 ° C, and after high-temperature melting, high-pressure high-speed air or steam injection, and cooling, it becomes white "cotton" - aluminum silicate refractory fiber. It can be pressed into fiber blanket, board or woven into cloth to replace refractory bricks lining high temperature furnaces in smelting, chemical, glass and other industries. Firefighters can use fire-resistant fiber cloth to make clothes.

- 5. Using magnesia and bauxite clinker as raw materials and adding appropriate binder, it is very effective for pouring the overall lining of the ladle.

- 6. Manufacture of bauxite cement, abrasive materials, various compounds that can be used to make aluminum in the ceramic industry and the chemical industry.

How to process bauxite powder?

The bauxite milling process flow is as follows:

1. Crushing of raw materials

The bulk bauxite material is crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.2. Grinding (Raymond mill ,ultrafine grinding mill or vertical mill)

The crushed small bauxite materials are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.3. Grading

The pulverized materials are classified by the classification system, and the unqualified powders are classified by the classifier and then returned to the main engine for re-grinding.4. Collection of Finished Products

The powder that meets the fineness enters the dust collector through the pipeline with the airflow for separation and collection, and the collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is uniformly packed with a powder tanker or an automatic baler.HGM ultrafine grinding mill for Bauxite

HGM ultrafine grinding mill is suitable for the super fine grinding of all kinds of crisp materials whose Mohs hardness is below 7, such as bauxite, calcium carbonate, barite, dolomite, calcite, limestone, kaolin, bentonite, marble, gypsum, quartz, feldspar, clay, talc, fluorite, white mud, mica, refractory material, glass, total about 1000 kinds of materials.HGM ultrafine grinding mill has advantages of:

1.The yield is 40% higher than other mills.

2.High utilization rate of Wear material:2-5years.

3.Adjustable particle size:325-3000mesh.

4.High safety and reliability. The design of the mill is rigorous, so no screw loosening to damage the machine.

5.Closed system, so it is the green and ideal equipment for environment protection.

Related Newsmore >>

- Happy New Year 2026!2026-01-01

- CLIRIK Welcomes a Surge of Visitors During CHINACOAT 2025 Season — Free Shuttle to Pudong Showroom2025-11-25

- Ultrafine Grinding of Recovered Carbon Black (rCB) Using HGM Mill2025-10-23

- HGM Ultrafine Grinding Mill for Limestone in Cement Industry2025-10-15

- Happy China National Day 20252025-09-29

- CLIRIK Ships HGM Mill to India: Fine Limestone Powder for Rubber & Plastic Fillers2025-09-25