What is the hourly output of 800 mesh kaolin clay processed by HGM grinding mill?

Source:nclirik

Posted:2021-06-18

800 mesh calcined kaolin clay micro-grinding equipment, CLIRIK's HGM ultrafine grinding mill has a simple process for producing 800 mesh calcined kaolin clay, with high pulverizing efficiency, and a single machine can reach 0.5 to 45 tons per hour. CLIRIK kaolin clay Ultrafine Mill is stable, energy-saving, environmentally friendly, and suitable for various needs. This article describes in detail this cost-effective HGM ultra-fine ring roller mill as a milling machine for the 800 mesh calcined kaolin clay process.

800 mesh calcined kaolin clay is an important industrial non-metallic mineral, its scientific name is hydrous aluminum silicate (aluminosilicate clay mineral), and its chemical composition is Al2O3 2SiO2 2H2O. It is a light gray flake powder with a triclinic crystal form with a quasi-hexagonal configuration. The specific gravity is 2.8, the hardness is 1.0 on the Mohs, and the refractive index is 1.56. It is a slightly acidic mineral, but still has good acid and alkali resistance. In addition to the characteristics of general mineral powder, it has a significant blocking effect on infrared rays, but it is easy to absorb moisture. It should be dried before use. The calcined kaolin clay product produced by CLIRIK HGM ultra-fine ring roller mill has high whiteness and covering power. Strong, bright, fine particle size, fast adsorption speed, excellent acid and alkali resistance, moderate oil absorption, stable physical and chemical properties, etc., is a new type of plastic additive, widely used in papermaking, coatings, inorganic pigments, cable ceramics, medicine , Organic polymer industry, grinding wheel, building materials and other industries.

800 mesh superfine calcined kaolin clay is widely used in plastics, rubber, ceramics, glass, paints, inks, coatings, electronics and other fields.

HGM ultra-fine ring roller mill is an ultra-fine grinding equipment newly developed by Shanghai CLIRIK Machinery Co.,Ltd. accumulated years of experience in production and research and development. The grinding mill equipment has comprehensive mechanical pulverization properties such as roller compaction, milling, and impact. It is widely used in kaolin clay, kaolin clay, calcium carbonate, dolomite, potash feldspar, bentonite, kaolin clay, graphite, carbon and other ultra-fine crushing of various non-metallic minerals with Mohs hardness below 7 and humidity within 6%, which is truly efficient and energy-saving , Especially suitable for ultra-fine crushing equipment for deep processing of non-metallic minerals.

HGM ultra-fine ring roller mill equipment has a small footprint, strong complete set, wide use, simple operation, convenient maintenance, stable performance and high cost performance. It is a highly efficient and energy-saving ultra-fine powder processing equipment. The feed size is less than or equal to 20mm, the fineness of the finished product is 0.1-0.005mm, and the output range is 0.7-45t/h.

Ultra-fine powder kaolin clay mill equipment-HGM ultra-fine ring roller mill model parameters are as follows:

The price of kaolin clay grinder is closely related to the model of kaolin clay high-pressure mill. The choice of model depends on the fineness and output requirements of kaolin clay powder. The fineness and output of kaolin clay powder determine the selection of kaolin clay milling equipment.

Different models of kaolin clay powder mills will result in different types of supporting equipment, which will naturally lead to different prices. So please provide the kaolin clay fineness and output requirements you need. CLIRIK's grinding mill technicians and program configuration personnel will configure according to your requirements, and the industry will issue a complete set of milling production line quotations.

Would like to know more about the price of CLIRIK 800 mesh calcined kaolin clay superfine grinding mills, kaolin clay Raymond mill, kaolin clay vertical mill, kaolin clay fine powder mill, kaolin clay Raymond mill, please call or leave a message online.

Email: [email protected]

WhatsApp: 008613917147829/ 008613512155195

1. 800 mesh calcined kaolin clay powder uses

800 mesh calcined kaolin clay is an important industrial non-metallic mineral, its scientific name is hydrous aluminum silicate (aluminosilicate clay mineral), and its chemical composition is Al2O3 2SiO2 2H2O. It is a light gray flake powder with a triclinic crystal form with a quasi-hexagonal configuration. The specific gravity is 2.8, the hardness is 1.0 on the Mohs, and the refractive index is 1.56. It is a slightly acidic mineral, but still has good acid and alkali resistance. In addition to the characteristics of general mineral powder, it has a significant blocking effect on infrared rays, but it is easy to absorb moisture. It should be dried before use. The calcined kaolin clay product produced by CLIRIK HGM ultra-fine ring roller mill has high whiteness and covering power. Strong, bright, fine particle size, fast adsorption speed, excellent acid and alkali resistance, moderate oil absorption, stable physical and chemical properties, etc., is a new type of plastic additive, widely used in papermaking, coatings, inorganic pigments, cable ceramics, medicine , Organic polymer industry, grinding wheel, building materials and other industries.

800 mesh superfine calcined kaolin clay is widely used in plastics, rubber, ceramics, glass, paints, inks, coatings, electronics and other fields.

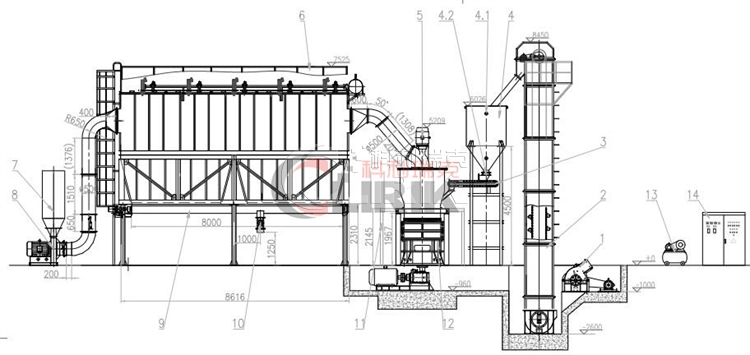

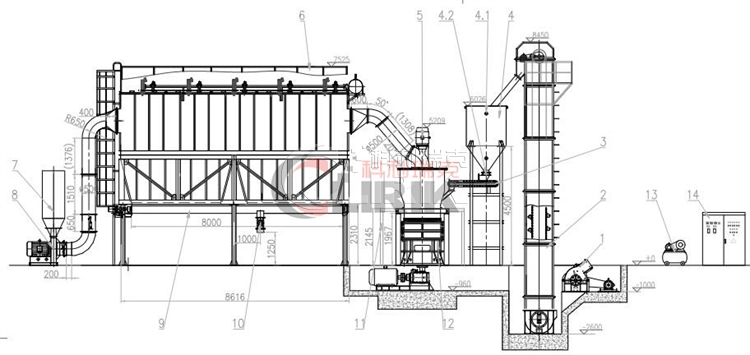

2. 800 Mesh Calcined Kaolin Clay Powder Process-CLIRIK HGM superfine ring roller mill 800 mesh calcined kaolin clay process-Calcined kaolin clay powder production process

- The first stage: calcined kaolin clay crushing: Large pieces of calcined kaolin clay are transported by special vehicles to the raw material warehouse, and then the materials are sent to the jaw crusher by forklifts/manually for crushing, and crushed to be smaller than the feed size of the ultra-fine ring roller mill (less than 10mm).

- The second stage: calcined kaolin clay feedstock: The kaolin clay crushed by the crusher is lifted by the elevator to the storage hopper, and the storage hopper is discharged and fed to the main machine evenly by the feeder

- The third stage: grinding with a mill: After the calcined kaolin clay enters the ultra-fine ring roller mill, the qualified products of the grinding are screened by the screening system and then enter the collector through the pipeline. After the collection, the calcined kaolin clay powder is discharged through the discharge valve to be the finished product, and the unqualified powder falls into the ultra-fine powder. Re-grind in the main machine of the fine ring roller mill.

- Fourth stage: Finished product collection: The calcined kaolin clay powder enters the pulse dust collector through the ventilation pipe connected with the mill, and the calcined kaolin clay powder enters the powder collector and waits for packaging. The airflow after pulse dust collection and purification flows into the blower through the residual air pipe above the dust collector. The air path is cyclic. Except for the positive pressure from the blower to the grinding chamber, the airflow in the rest of the pipeline flows under negative pressure. Indoor sanitary conditions better.

3. HGM ultra-fine ring roller mill for 800 mesh calcined kaolin clay

HGM ultra-fine ring roller mill is an ultra-fine grinding equipment newly developed by Shanghai CLIRIK Machinery Co.,Ltd. accumulated years of experience in production and research and development. The grinding mill equipment has comprehensive mechanical pulverization properties such as roller compaction, milling, and impact. It is widely used in kaolin clay, kaolin clay, calcium carbonate, dolomite, potash feldspar, bentonite, kaolin clay, graphite, carbon and other ultra-fine crushing of various non-metallic minerals with Mohs hardness below 7 and humidity within 6%, which is truly efficient and energy-saving , Especially suitable for ultra-fine crushing equipment for deep processing of non-metallic minerals.

HGM ultra-fine ring roller mill equipment has a small footprint, strong complete set, wide use, simple operation, convenient maintenance, stable performance and high cost performance. It is a highly efficient and energy-saving ultra-fine powder processing equipment. The feed size is less than or equal to 20mm, the fineness of the finished product is 0.1-0.005mm, and the output range is 0.7-45t/h.

Ultra-fine powder kaolin clay mill equipment-HGM ultra-fine ring roller mill model parameters are as follows:

- Name: HGM ultra-fine ring roller mill/HGM micro powder grinding mill

- Models: HGM80, HGM90, HGM100, HGM125, HGM1680, etc.

- Input Size: ≤20mm

- Power: 144-680KW

- Weight: 17.5-70 t

- Capacity: 0.5-45t/h

- Output Size: 0.1-0.005mm / 30-3000 mesh

- Grinding Field: For various non-metallic mineral materials with Mohs hardness below level 7 and humidity below 6%, this mill is widely used for kaolin clay, kaolin clay, calcium carbonate, dolomite, potash feldspar, and bentonite The grinding and processing of kaolin clay, graphite, carbon and other materials are widely used in the fields of electric power, metallurgy, cement, chemical industry, non-metallic mineral powder, food, medicine and so on.

- Performance Features: Ultra-fine kaolin clay powder grinding mill HGM ultra-fine ring roller mill has comprehensive mechanical crushing properties such as roller compaction, milling, impact, etc., focusing on the field of deep processing of non-metallic minerals, with a small footprint and strong complete set , Wide use, simple operation, convenient maintenance, stable performance, high efficiency and energy saving.

4. About the price of kaolin clay powder grinding mill

The price of kaolin clay grinder is closely related to the model of kaolin clay high-pressure mill. The choice of model depends on the fineness and output requirements of kaolin clay powder. The fineness and output of kaolin clay powder determine the selection of kaolin clay milling equipment.

Different models of kaolin clay powder mills will result in different types of supporting equipment, which will naturally lead to different prices. So please provide the kaolin clay fineness and output requirements you need. CLIRIK's grinding mill technicians and program configuration personnel will configure according to your requirements, and the industry will issue a complete set of milling production line quotations.

Would like to know more about the price of CLIRIK 800 mesh calcined kaolin clay superfine grinding mills, kaolin clay Raymond mill, kaolin clay vertical mill, kaolin clay fine powder mill, kaolin clay Raymond mill, please call or leave a message online.

Email: [email protected]

WhatsApp: 008613917147829/ 008613512155195

Related Newsmore >>

- Happy New Year 2026!2026-01-01

- CLIRIK Welcomes a Surge of Visitors During CHINACOAT 2025 Season — Free Shuttle to Pudong Showroom2025-11-25

- Ultrafine Grinding of Recovered Carbon Black (rCB) Using HGM Mill2025-10-23

- HGM Ultrafine Grinding Mill for Limestone in Cement Industry2025-10-15

- Happy China National Day 20252025-09-29

- CLIRIK Ships HGM Mill to India: Fine Limestone Powder for Rubber & Plastic Fillers2025-09-25