Benefits of 50-3000 Mesh Kaolin Powder Milling Machines

1. Have finely, coarse grinding function.

2. High reliability, strict safety device to ensure equipment and personal safety.

3. Vortex chamber internal air circulation, dust pollution is small.

4. The structure of 50-3000 Mesh Kaolin Powder Milling Machines is simple and reasonable, self crushing, ultra-low cost of use.

5. Unique bearing installation with advanced spindle design, so that the machine has the characteristics of heavy load and high speed rotation.

6. Smooth operation, low noise, high efficiency and energy saving, high crushing efficiency.

7. Affected by the moisture content of the material is small. The moisture content can reach about 8%.

8. Impeller and vortex crushing cavity material lining greatly reduces the cost of wear parts and maintenance workload.

9. Wear parts loss is low, all wearing parts of 50-3000 Mesh Kaolin Powder Milling Machines are used at home and abroad high quality wear-resistant materials, long service life. A small number of easily worn parts made of hard and wear-resistant materials, small size, light weight, easy replacement parts.

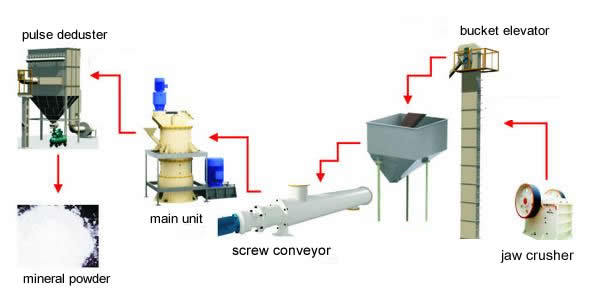

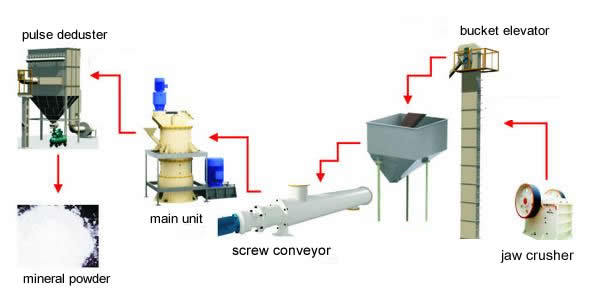

Working principle of 50-3000 Mesh Kaolin Powder Milling Machines

Vibrating feeder evenly send materials into the host and continuously grinding in mill room, after grinding, the powder will flow up by the wind machine, and classified by the classifier, the standard powder will flow through the pipe into the powder collector, the collection is separated by a valve discharge, and this is the final product.

Kaolin is a soft white mineral that has a large array of uses. It is most commonly found in the form of a fine clay that was originally produced in China, which is why this material is sometimes referred to as “China clay.” Among the many uses for this mineral are the paper industry, medications, skincare products, porcelain, and cosmetics. Sources of it can be found all over the world, including the United States, China, Brazil, Australia, and parts of Eastern Europe.

Kaolin is a soft white mineral that has a large array of uses. It is most commonly found in the form of a fine clay that was originally produced in China, which is why this material is sometimes referred to as “China clay.” Among the many uses for this mineral are the paper industry, medications, skincare products, porcelain, and cosmetics. Sources of it can be found all over the world, including the United States, China, Brazil, Australia, and parts of Eastern Europe.